Cervical Collars

Cervical collars are neck braces used for suspected spinal trauma and for post-surgical stabilization of the spine. Current cervical collars allow too much freedom of movement and have limited options for an individualized fit. I am using granular jamming and 3-D printing to resolve those problems. Granular jamming occurs when granular media, like coffee grounds, are placed under vacuum and become hard and rigid; by contrast, when not under vacuum, the bladder can be molded to the patient’s neck.

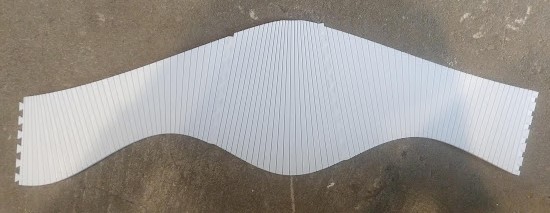

(left) Nitrile rubber pouch filled with coffee grounds; attached syringe is used to pull a vacuum. (right) 3D printed shell laid flat.

The previous prototype uses channels cut into a flat print at varying angles and spacing to allow the collar to fold up into a complex 3-D shape rather than a simple cone or cylinder. I used a 3-D scan of a person’s head, neck, and shoulders to create the initial 3-D part. Then, using Solidworks tools and a VBA script, I was able to flatten the collar into a printable shape. I placed in the top 10 engineering projects at LSU’s Discover Day of Spring 2021 with that design.

Collar shell on person in SolidWorks.

Printed collar top view.

Printed collar side view.

The next iteration involves cutting out the middle section of the 3-D printed shell to create two rings. These rings will then be connected by adjustable length struts to form a Stewart’s platform1. This allows complete control of the rings position relative to each other. The nitrile rubber bladders fill the space between the collar and the neck.

Generic Stewart-Gough platform.

Collar shell prototpye inspired by the Stewart-Gough platform shown in SolidWorks.

He, Jianjun & Gu, Hong & Wang, Zhelong. (2013). Solving the forward kinematics problem of six-DOF Stewart platform using multi-task Gaussian process. Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science. 227. 161-169. 10.1177/0954406212444508. ↩︎